OUR PRODUCTS

Precision Crafted Solutions, Trusted Performance, and Value for Your Investment – Our Commitment

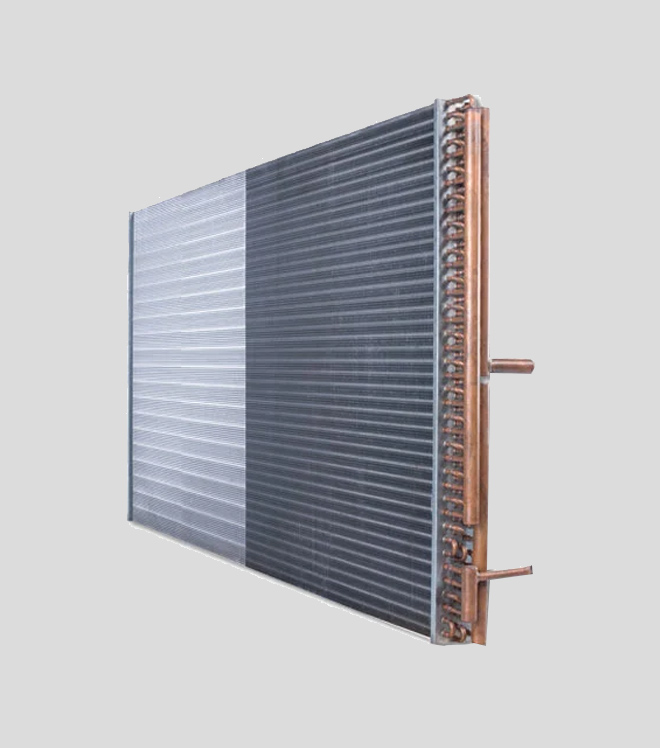

End Connection material can be of copper or schedule 40 Mild steel. End Connections can be of welded, threaded or Flanged pipe with drain plugs for easy maintenance.

Headers of Seamless Mild Steel or Copper material with Type- T or L are provided based on requirements.

Coil casing material shall be 16 or 18-gauge of Galvanized Steel, Copper or Stainless Steel. Heavier gauge and optional material casings are available as required to meet specifications. Intermediate supports are provided on all coils 50” and longer in fin length. Coil casings on top and bottom of coils are to have double-flanged construction allowing vertical stacking of coils.

Aluminum fins are of the plate-fin design using aluminum or copper, with die-formed collars. The fin design is to be flat or sinewave in a staggered tube pattern to meet the required parameters. Collars will hold fin spacing at specified density and cover the entire tube surface. Aluminum properties are to be Alloy 1100 per ASTM B209, with half hard temper; copper of Alloy 11000 as per ASTM B152-06 with soft temper.

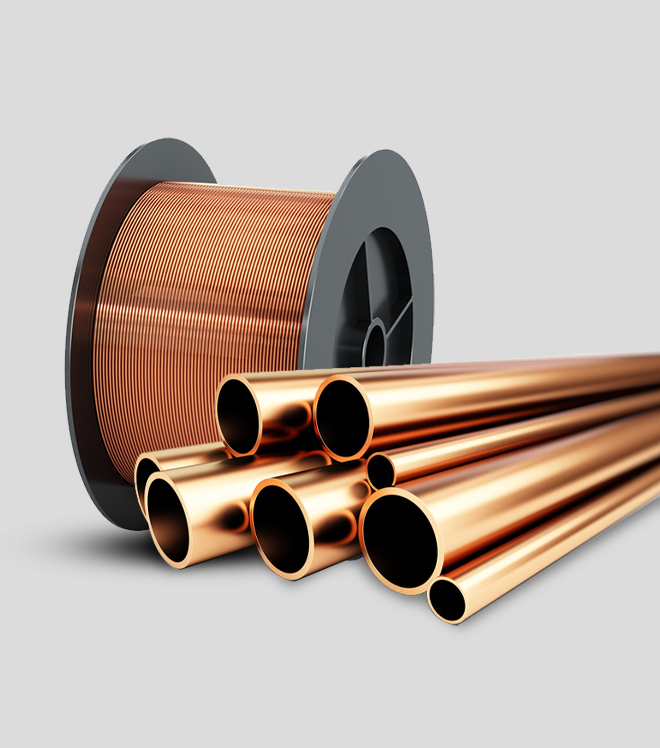

Tubes and U-bends bends shall be constructed from seamless C12200 copper conforming to ASTM B75 and ASTM B743. Hydraulic Expansion of Seamless tubes are carried out into plate fins for maximum heat transfer.

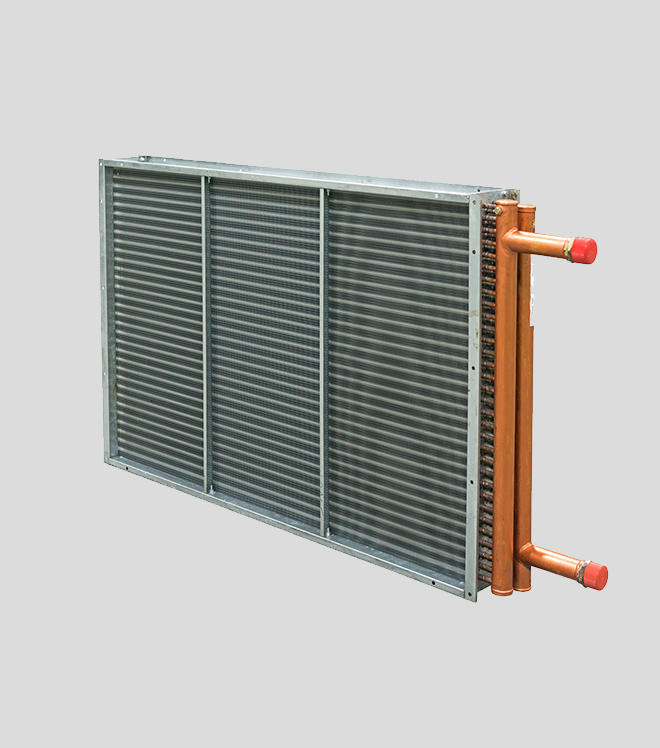

Hot water coils are integral components in HVAC systems, used for heating applications. These coils comprise a network of pipes through which hot water flows. When air passes over the coils, the heat from the water is transferred to the air, warming it before distribution. Thermowell Technologies excels in this domain with a proven track record in designing and manufacturing high-performance hot water coils. Their expertise lies in precise coil design, material selection, and engineering, ensuring optimal heat transfer efficiency. With a commitment to quality and tailored solutions, Thermowell consistently delivers reliable and energy-efficient hot water coil systems for various industries, enhancing indoor comfort and energy savings.

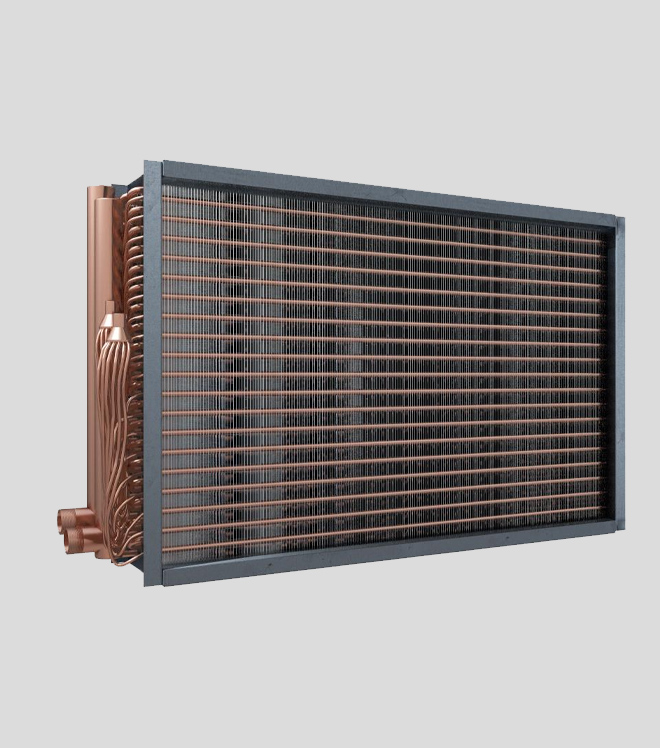

A finned tube heat exchanger is a crucial device for efficiently transferring heat between two fluids. It consists of a network of tubes, typically made of metals like copper or aluminum, with finned surfaces attached to enhance heat transfer. The exchange occurs when one fluid passes through the tubes while the other flows over the finned surfaces. Thermowell Technologies is an expert in this domain due to its extensive experience and a commitment to quality. They design and manufacture highly efficient finned tube heat exchangers tailored to specific applications, ensuring optimal heat transfer, reliability, and durability in various industries, including aerospace, pharmaceuticals, and industrial sectors. Their expertise lies in delivering precision-engineered solutions that meet diverse customer needs.

An evaporator is a key component in refrigeration and air conditioning systems. It is typically located inside the indoor unit and plays a crucial role in the cooling cycle. The evaporator consists of coils containing a refrigerant. When the system is in operation, the low-pressure, low-temperature liquid refrigerant enters the evaporator. As warm air from the surroundings is blown over the coils, the refrigerant absorbs heat from the air, causing it to evaporate into a low-pressure gas. This heat absorption cools the air and removes humidity. The cooled and dehumidified air is then circulated into the living or working space, providing a comfortable and controlled indoor environment.

A Direct Expansion (DX) coil is a critical component in air conditioning systems. It comprises a network of copper or aluminum tubing that carries a refrigerant. During operation, a compressor pressurizes the refrigerant into a high-temperature, high-pressure gas. This gas is then directed into the DX coil, where it passes through the coil's tubes. As warm air from the space is blown over the coil, the refrigerant releases heat, causing it to evaporate. This process cools and dehumidifies the air. The now-cooled air is then distributed throughout the building. DX coils are efficient and widely used in residential and commercial air conditioning systems for space cooling.

Cooling coils, commonly found in air conditioning and refrigeration systems, play a pivotal role in heat removal and temperature regulation. They consist of a network of tubes and fins. As warm air is drawn over the coils, a refrigerant inside the tubes absorbs heat from the air, causing the refrigerant to evaporate. This phase change removes heat from the surrounding space, cooling the air. The coils also dehumidify the air by condensing moisture. The cooled and dehumidified air is then circulated back into the living or storage space, providing a more comfortable environment. Cooling coils are integral to maintaining indoor temperature and humidity levels efficiently.

A chilled water coil is a crucial component in air conditioning systems. It consists of a network of tubes and fins designed to efficiently transfer heat. Chilled water circulates through the tubes, absorbing heat from the surrounding air. As warm air from a building is drawn over the coil, the heat is transferred to the chilled water, cooling the air in the process. This cooled air is then distributed throughout the building, creating a more comfortable indoor environment. Chilled water coils are commonly used in commercial HVAC systems, providing an energy-efficient method of air conditioning by leveraging water's superior heat-absorbing properties.

Cold room indoor units, often referred to as evaporators or air coolers, are vital components in cold storage facilities. These units help maintain precise temperature and humidity levels within the cold room. They consist of coils and fans that work together to remove heat and humidity from the room's air. The evaporator coils contain a refrigerant that evaporates, absorbing heat from the surroundings. The fans then distribute the cooled air evenly throughout the storage space, ensuring uniform temperatures and preserving the quality and safety of stored products. These indoor units are essential for various industries, including food storage, pharmaceuticals, and research facilities, where temperature control is critical.

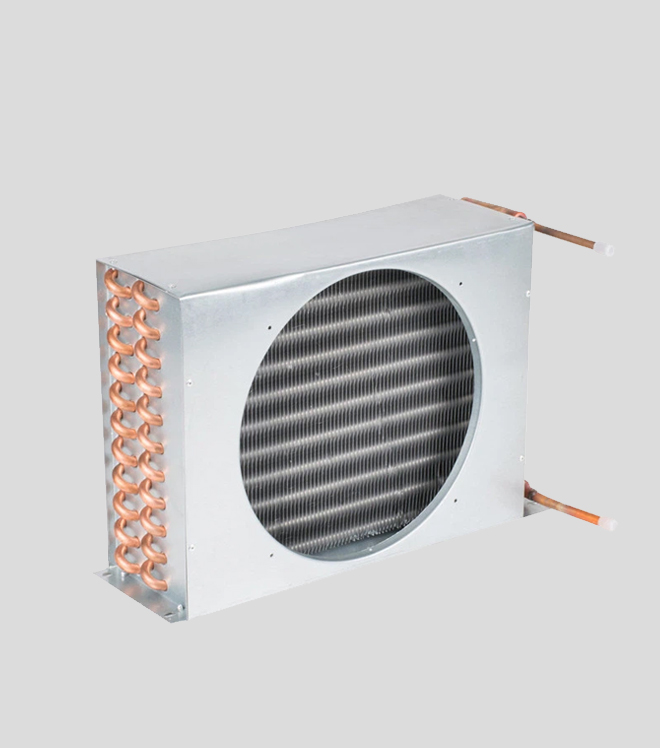

Condenser coils in heat pumps play a crucial role in the heat transfer process. These coils are located in the outdoor unit of the heat pump. During the heating mode, the condenser coil receives high-pressure, high-temperature refrigerant vapor from the compressor. As outdoor air is drawn over the coil, the refrigerant releases its heat, transferring it to the air. This process causes the refrigerant to condense into a high-pressure liquid. In the cooling mode, the direction of heat transfer reverses, with the condenser coil expelling heat from the indoor space. Efficient condenser coils are essential for the heat pump's overall performance, enabling it to provide both heating and cooling functions effectively.

Condenser coils are a vital component in refrigeration and air conditioning systems. These coils are typically located in the outdoor unit of such systems. They facilitate the release of heat from the refrigerant, which has been compressed into a high-pressure, high-temperature gas by the compressor. As outdoor air is blown over the condenser coils, the refrigerant releases heat, causing it to condense into a high-pressure liquid. This transformation is essential for the cooling cycle in air conditioners and refrigeration, as it allows the refrigerant to release heat to the external environment, enabling the system to maintain lower indoor temperatures or preserve the cold storage of food and other perishables.

| Copper Tube Sizes (OD) | Tube Thickness (in mm) | Temper | Standard |

|---|---|---|---|

| 3/8” IG or Plain | 0.28 / 0.30 | O50 / O60 | ASTM B68 |

| ½” | 0.32 / 0.36 / 0.41 | O50 / O60 | ASTM B68 |

| Fin Material | Fin Thickness (in mm) | Fin Design | Fins per Inch (FPI) |

|---|---|---|---|

| Copper | 0.12 / 0.13 | Flat / Sine Wave | 11-14 FPI |

| Aluminum | 0.14 / 0.15 | Flat / Sine Wave | 10-13 FPI |

| Casing Material | Thickness (in mm) | Flange Size - End Plates (in mm) | Top and Bottom Design |

|---|---|---|---|

| Copper | 1.2 / 1.6 | 40 / 30 / 25 | Box / C-type |

| Aluminum | 1.2 / 1.5 | 40 / 30 / 25 | Box / C-type |

| Galvanized Steel | 1 / 1.2 / 1.5 | 40 / 30 / 25 | Box / C-type |

| Header Material | Thickness (in mm) | End Connection Position | End Connection |

|---|---|---|---|

| Copper | 1.2 / 1.6 | L / T – type, RHS / LHS | Welded / Flange / Threaded |

| Mild Steel | 3 / 4 | L / T – type, RHS / LHS | Welded / Flange / Threaded |